Salt Chlorination

Benefits explained, myths dispelled and an explanation of how it works

Soft on the Skin

Saves Money

No Odour

Stable Sanitation

The Science Behind the Salt

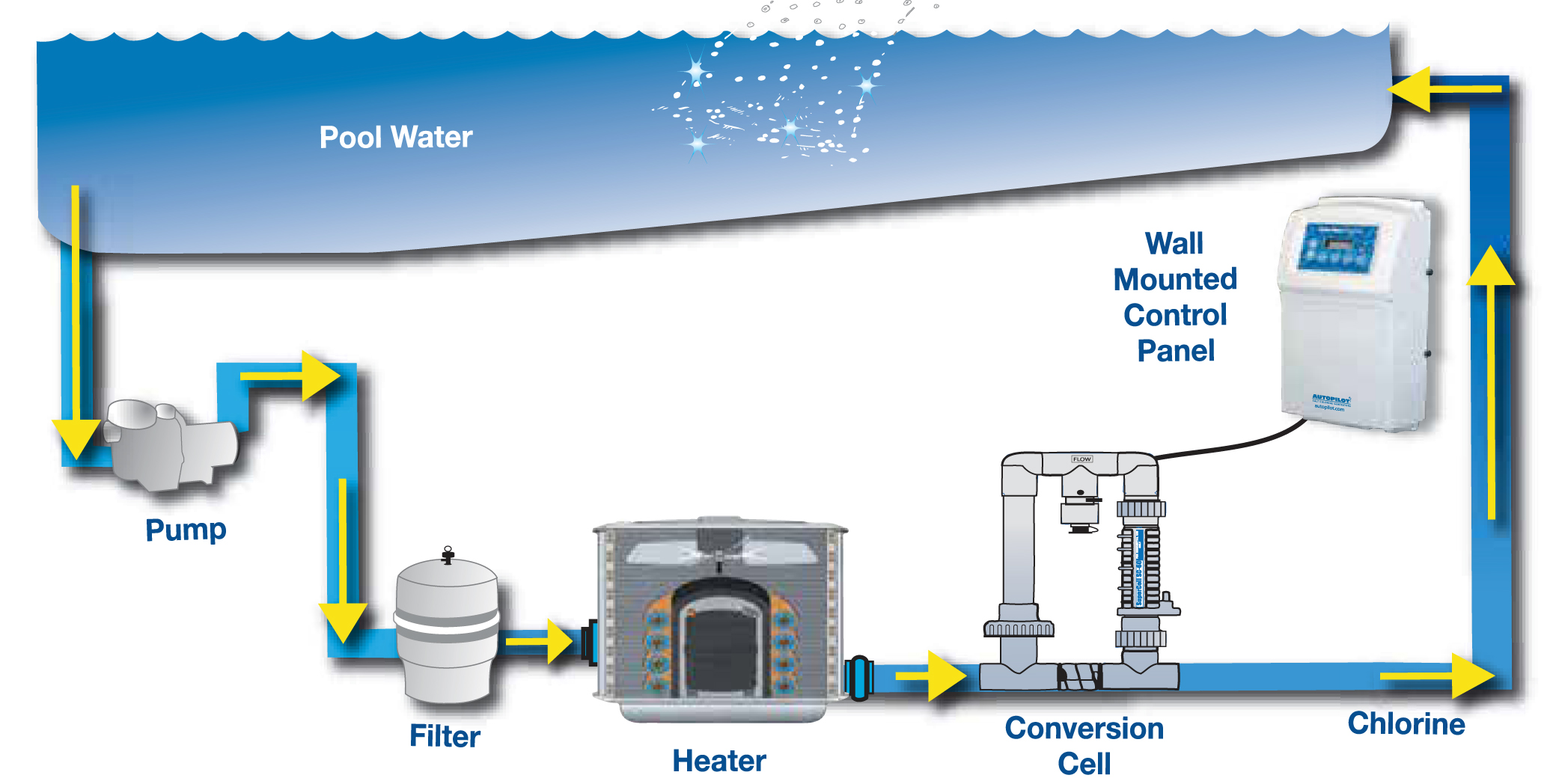

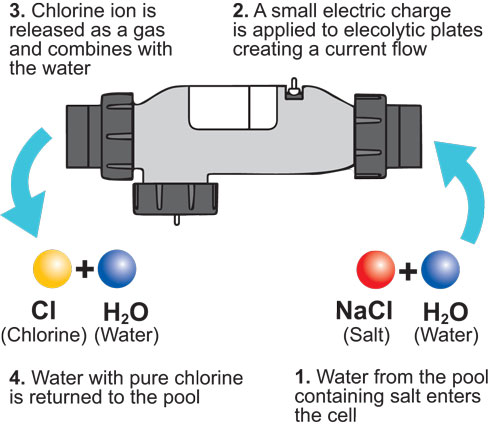

Salt is added to pool water in conjunction with the installation of a salt chlorine generator. The generator is comprised of a power supply which is wired at the pool equipment pad and a salt cell which is plumbed inline with the pipe returning water to the pool. Inside the salt cell are coated metal blades which receive a low voltage current. As salt water passes through, electrolysis occurs, splitting the salt and water into hydrogen and hypochlorous acid. This acid replaces the chlorine tablets or granules traditionally used to sanitize pools.

This process repeats indefinitely as the salt converts to acid and then the acid converts back to salt. Salt does not evaporate. Therefore, once the proper ppm of salt is reached, only small amounts of salt are required to adjust levels. Some things that affect salt levels are heavy rain, which dilutes the concentration of salt, or heavy pool usage (think pool party), when a significant amount of water might be splashed out of the pool.

High Quality Chlorine

The chlorine produced by this electrolytic process is less harsh than the traditional “tri-chlor” chlorine used for pools. Chlorine created from salt does not smell like bleach, and is very gentle to skin, hair and swim suits. The water has a softer feel. These are the more aesthetic benefits of using a salt chlorine generator. Other pros include not having to buy, handle or store buckets of chlorine. It is also considered to be a purer and therefore healthier form of chlorine, for those interested in limiting their exposure to this potent chemical.

Distinction from traditional pool chlorination

The presence of chlorine in traditional swimming pools can be described as a combination of free available chlorine (FAC) and combined available chlorine (CAC). While FAC is composed of the free chlorine that is available for sanitizing the water, the CAC includes chloramines, which are formed by the reaction of FAC with amines (introduced into the pool by human perspiration and urine). Chloramines are responsible for the “chlorine smell” of pools, as well as skin and eye irritation. These problems are the result of insufficient levels of free available chlorine, and indicate a pool that must be “shocked” by the addition of 5-10 times the normal amount of chlorine. In saltwater pools, the generator uses electrolysis to continuously produce free chlorine. It also burns off chloramines in the same manner as traditional shock (oxidizer). As with traditionally chlorinated pools, saltwater pools must be monitored in order to maintain proper water chemistry. Low chlorine levels can be caused by insufficient salt, higher-than-normal chlorine demand, low stabilizer, sun exposure, or mechanical issues with the generator. Salt count can be lowered due to splash-out, backwashing, and dilution via rainwater.

Operation

The chlorinator cell consists of parallel titanium plates coated with ruthenium and sometimes iridium. Older models make use of perforated (or mesh) plates, rather than solid plates. Electrolysis naturally attracts calcium and other minerals to the plates. Thus, depending on water chemistry and magnitude of use, the cell will require cleaning in a mild acid solution (1 part HCl to 15 parts pool water) which will remove the buildup of calcium. Excessive build up can reduce the effectiveness of the cell. Running the chlorinator for long periods with not enough salt in the pool can strip the coating off the cell which then requires an expensive replacement, as can using too strong an acid wash.

Saltwater pools can also require stabilizer (cyanuric acid) to help stop the sun’s UV rays from breaking down free chlorine in the pool. Usual levels are 20 – 50 ppm. They also require the pH to be kept between 7.2 and 7.8 with the chlorine being more effective if the pH is kept closer to 7.2. The average salt levels are usually in the 3000-5000 ppm range, much less than the ocean, which has salt levels of around 35,000 parts per million (ppm). Typically, salt is poured across the bottom of the pool and swept with the pool brush until it dissolves; if concentrated brine is allowed into the return-water system it can cause the chlorinator cell to malfunction due to overconductivity.

Salt water chlorination produces an excess of hydroxyl ions whilst releasing chlorine from salt, which makes the pool alkaline (sodium hydroxide, NaOH, caustic soda) . This requires the frequent addition of Hydrochloric Acid (HCl) to neutralise the alkalinity and convert the sodium hydroxide back into Sodium Chloride (i.e. table salt), which can be split by electrolysis again . Thus the consumable supplying all the chlorine is in fact the hydrochloric acid, with the salt acting as a non-consumed intermediary, being split and reformed . The whole process is exactly balanced by equivalents : the amount of chlorine produced is directly related to the amount of hydrochloric acid used, other things remaining equal . This could be represented roughly as follows (with the ions all separated in solution):

-

-

-

-

-

-

-

2NaCl + 2H

2O → electrolysis → 2NaOH + H

2 + Cl

2 -

2NaOH + 2HCl → chemical reaction → 2NaCl + 2H

2O

-

-

-

Net reaction : 2HCl → → → H

2 + Cl

2 (as gases bubbling off) .

-

-

-

-

Use of another acid, such as sulphuric acid, to neutralise pool alkalinity will neutralise the pH but will produce sulphate ions rather than chloride ions . Sulphate ions will conduct electricity equally well as chloride at the electrode, but will not produce any chlorine . A salt water pool “poisoned” with sulphate may have to be drained and refilled to remove the offending sulphate ions .

Benefits and Disadvantages

The benefits of salt systems in pools are the convenience and the constant delivery of pure chlorine-based sanitizer. The reduction of irritating chloramines versus traditional chlorinating methods and the “softening” effect of electrolysis reducing dissolved alkali minerals in the water are also perceived as benefits. For some people that have sensitivities to chlorine, these systems may be less offensive. Salt water pools are cheaper to maintain throughout the year, since salt is significantly cheaper than the commercial chlorines.

Disadvantages are the initial cost of the system, maintenance, and the cost of replacement cells. Salt is corrosive and will damage some metals and some improperly-sealed stone. However, as the ideal saline concentration of a salt-chlorinated pool is very low (<3,500ppm, the threshold for human perception of salt by taste; seawater is about ten times this concentration), damage usually occurs due to improperly-maintained pool chemistry or improper maintenance of the electrolytic cell. Pool equipment manufacturers will not warrant stainless steel products damaged by saline pools.

Calcium and other alkali precipitate buildup will occur naturally on the cathode plate, and sometimes in the pool itself as “scaling”. Regular maintenance of the cell is necessary; failure to do so will reduce the effectiveness of the cell. Certain designs of saline chlorinators use a “reverse-polarity” design that will regularly switch the roles of the two electrodes between anode and cathode, causing this calcium buildup to dissolve off the accumulating electrode. Such systems reduce, but do not eliminate, the need to clean the electrolytic cell and the occurrence of calcium scale in the water.

As chlorine is generated, pH will rise causing the chlorine to be less effective. Many systems with chemistry automation can sense the rising pH and automatically introduce either CO2 or hydrochloric acid in order to bring the pH back to the target level.

Automation systems will also manage levels of sanitizer by monitoring the ORP or redox levels of the water. This allows only the needed amount of chlorine to be generated based on the demand.

Sales, Installation & Service